Manufacturing ERP Systems UK

Moulders Consulting: Providing Top-Quality UK Manufacturing ERP Systems

At Moulders Consulting, our software is not just another ERP/MRP system; it’s a bespoke solution created by experts within the manufacturing industry for the manufacturing industry.

With a collective experience of over 40 years in manufacturing – spanning roles such as sales, marketing, operations, and management – we have successfully implemented numerous ERP/MRP systems within the sector.

MRP, short for Materials Requirements Planning, holds a pivotal role in ensuring that the right materials are available at the right time for producing high-quality products in the manufacturing process.

Here’s a simplified breakdown of the steps involved:

1) Determine The Production Schedule: This step involves creating a production schedule based on customer demand, inventory levels, and other critical factors. The result is a production plan outlining the quantity of products to be manufactured over a specified period.

2) Calculate Material Requirements: Once the production schedule is set, the next task is to calculate the material requirements. This calculation considers the quantity of products to be produced, the materials needed for each product, and any potential waste or scrap during production.

3) Check Inventory Levels: Following material requirement calculations, the system checks the inventory levels of the required materials. This step determines whether existing inventory meets production needs or if additional materials must be ordered.

4) Generate Purchase Orders: In cases of insufficient inventory, the MRP system generates purchase orders for the necessary materials. These orders include quantity, delivery dates, and other crucial information.

5) Track Progress: After placing purchase orders, the MRP system diligently tracks order progress, including delivery dates and any delays or issues that may arise.

6) Adjust The Plan: If any changes occur in the production schedule or delays/issues with materials, the MRP system dynamically adjusts the plan accordingly.

MRP is a vital process for effectively managing the materials required for injection moulding. It ensures that the right materials are available at the right time, a critical element in producing high-quality products in the industry.

Mark Amphlett

Director

Need help? Contact me

01626 903 151 or mark@mouldersconsulting.co.uk

About Our Manufacturing ERP Systems UK

Our software combines the strengths of both MRP and ERP systems to deliver a comprehensive and seamlessly integrated production management solution designed exclusively for companies in the manufacturing industry. These tailored solutions are meticulously crafted to meet the unique requirements of the sector. They offer the means to efficiently streamline your operations at every level, resulting in enhanced efficiency and improved performance.

With over 40 years of experience, we are industry specialists with a profound understanding of the sector. We take pride in our track record of successfully implementing ERP and MRP systems in manufacturing companies of all sizes and types. Reach out to us to learn more about our industry-leading software and become a part of the next technological revolution in the manufacturing industry!

About Us

At Moulders Consulting Limited, we’re dedicated to forming partnerships with companies, helping them optimise their processes, reduce manufacturing costs, and boost profitability.

Our services are tailored to address your specific needs, including expert advice on ERP/MRP systems, implementation of Manufacturing Execution Systems (MES), production process optimisation, e-commerce solutions, marketing strategies, ancillary services, troubleshooting, and other aspects related to manufacturing.

Our ultimate aim is to support companies in achieving higher-quality products, increased operational efficiency, and reduced production costs, leading to heightened profitability. Drawing upon our extensive expertise in various facets of the manufacturing process, including the latest Industry 4.0 advancements, we can provide valuable guidance to enhance your production processes and bolster your marketing and sales initiatives.

Our services are known for delivering cost-effective consultancy, innovative products, and effective solutions that will elevate your operations and drive increased profitability for your company.

Our software is specifically crafted for ambitious manufacturing companies with an annual turnover ranging from approximately £1M to £25M.

Contact us today to discover how our software can boost operational excellence, increase profitability, and ensure sustained growth for companies in the manufacturing industry!

Looking For Top-Quality Manufacturing ERP Systems UK? Give Us A Call!

Want to know what our manufacturing ERP systems UK can do for you?

MCL Software - for the Injection Moulding Industry

Over 40 years experience within the Plastics Industry

2023 - The Year For Efficiency!

An all-encompassing, tried and tested ERP / MRP for the Injection Moulding Industry – the core software has been developed to cater for our complex industry, and we have the knowledge and grass routes experience having worked within Injection Moulding Factories, to fully understand the improvement in efficiencies required to make an ERP / MRP implementation really worthwhile. Communication is the key! Scroll on down to see just some of the key features of MCL Software.

MCL Software - Key Features

DASHBOARD – designed to give an overview of your facility – broken down into sections to include

Sales | Quotes | Purchasing | Production | Quality | Delivery

Navigate easily from your dashboard to access all ERP / MRP info – even through to production planning.

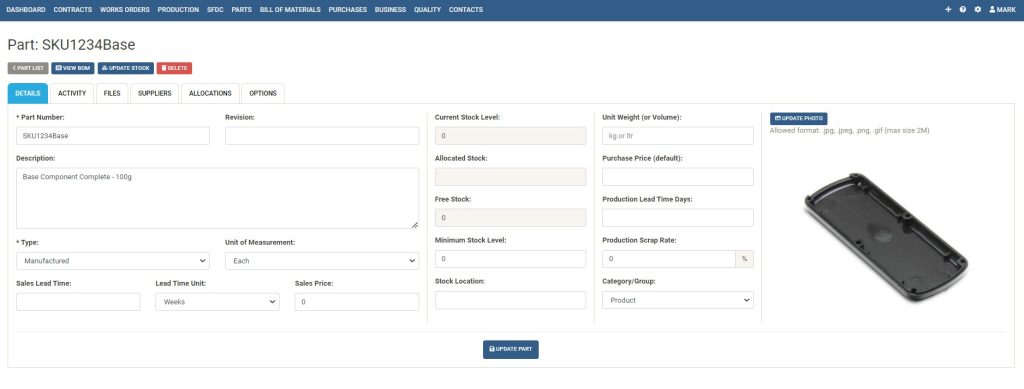

PARTS – see all of the information you need to about any manufactured or bought in part on one simple to use screen. Here you will have an overview of the following:

Part Details | Activity | Files | Suppliers | Allocations | Options

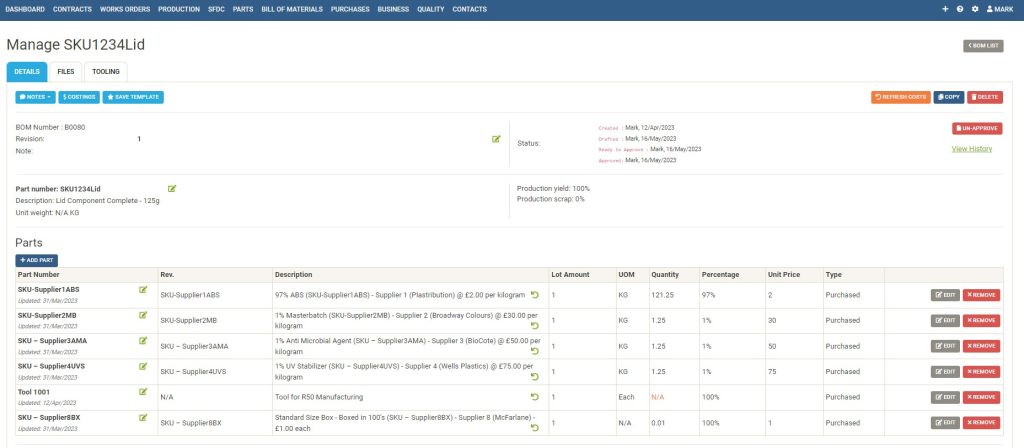

BOMS – easy to navigate and populate – able to select multiple items easily on the Bill of Material in a variety of units, including percentages to jobs which may include Masterbatch, UV Stabaliser, Powders, Anti-Microbial agents etc.

Add files, quality documents, C of C’s, and tooling data to ensure all relevant detail can be accessed in one clear and concise location.

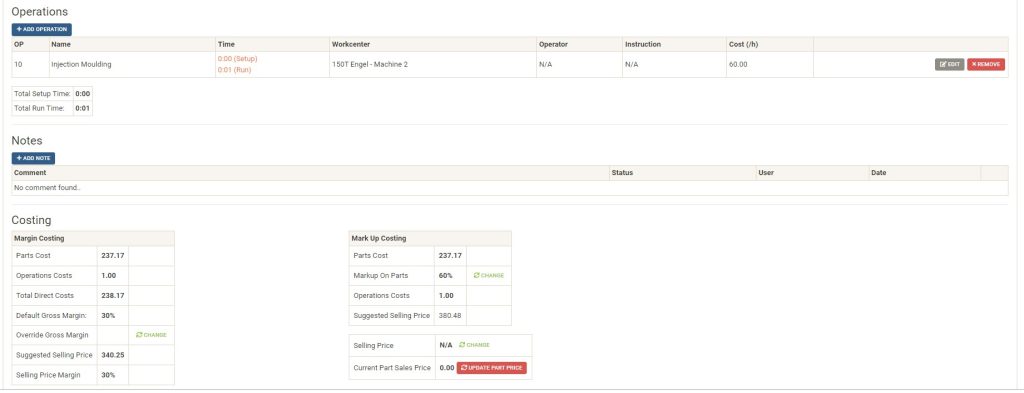

BOMS – You then delve deeper into the detail of the specified machine best suited for the manufacture of this component and add on any ancillaries required including robots, conveyors, dryers, and even the human resources required for production.

Add notes that are relevant to the job, and the additional bonus of the costing calculator gives you the ability to track profitability, and calculate price breaks by relating the part cost, to various quantities, and your required margin.

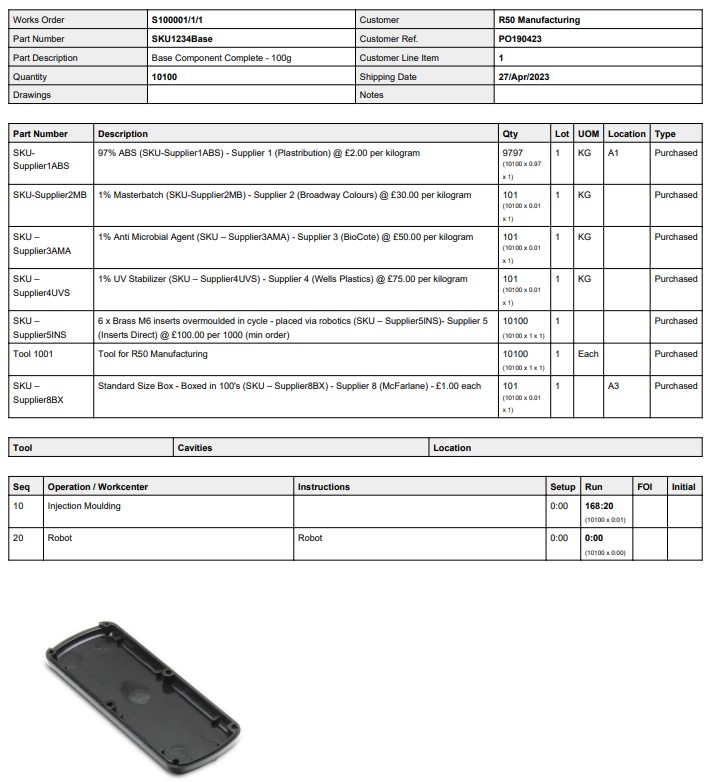

JOB CARD – All of the right information, all in the right place. The MCL Job Card clearly shows the following:

Work Order No. | Part Number | Description | Job Quantity | Drawing

Customer | P/O Ref No | Order Line | Date | Notes

BOM details, to include quantities, weights, units of measure, locations, and type of product

Tool information, including location, change inserts, and cavities are provided

Allocation of machines and any ancillaries required to complete production

And finally, the image of the part itself to help the production personnel to keep on track.

MCL Software - Key Features

Tooling Register

Incorporating a full tooling register, maintaining your clients tooling status and location

BOM's

Multi-level Bill Of Materials, to include sub-assemblies, and final assemblies

Production Planning

Visual Capacity planning and scheduling, by the Week, Day and even Hour

Job Cards / Works Orders

A clear visual document for shop floor use - including BOMs for Injection Moulding

Contacts

Full customer and Supplier data capture with CRM Traceability and email capabilities throughout

Traceability

Ability to trace material from Purchase Order through WIP to final moulded component

Second Operations

Ability to track manufacturing flow to clearly identify secondary operations and manual operations

Purchasing

Full purchase planning auto updated customer sales order demand, and stock allocations

NCR / Quality

Track all non-conformance reports and corrective actions, integrated with part record

Shop Floor Data Capture

Real time data collection from production - tracking all processes and works orders / job cards

Dashboard

Snapshot insight into daily business expectations, monitoring progress in real time

Invoicing

Raise invoices using our invoicing module, integrated directly with Sage, Xero & Quickbooks

Our Directors

About Mark Amphlett

With over 20 years of experience in the plastics industry, Mark Amphlett played a pivotal role in the growth of Amtek Plastics, Newton Abbot, as General Manager.

Under his leadership, the company’s annual turnover surged from £650k to over £3M in less than 6 years. Mark’s effective branding strategies positioned Amtek Plastics as a leading provider of Plastic Injection Moulding services in the UK, resulting in a significant increase in inbound inquiries, from an average of 3 or 4 per month up to a typical monthly total of well over 60.

These outcomes showcase Mark’s exceptional marketing skills, unwavering dedication to fostering growth, and remarkable talent for strategically positioning businesses to achieve success.

About Andy Jewell

Andy Jewell entered the plastics industry in 1989, with an Honours Degree in Chemistry with Business Administration.

During his early career, Andy gained invaluable experience in sales, developing his technical knowledge of material handling, drying, and dosing systems, as well as real-time Manufacturing Execution Systems (MES) for the Plastics sector.

As his expertise in the Plastic Injection Moulding industry developed, Andy transitioned into the promotion and sale of real-time Manufacturing Execution Systems (MES) for the Plastics sector.

Working closely with a renowned US-based supplier of MES/SFDC/i4.0 solutions, Andy played a crucial role in establishing them as a leading provider across the globe. His dedication and contributions helped to drive the company’s success and solidify its reputation within the industry.

As an Independent Sales Consultant since 2017, Andy’s deep understanding of the plastics industry and expertise in MES solutions make him a trusted advisor and consultant.

His commitment to excellence and delivering tangible results has helped numerous customers achieve enhanced productivity and profitability.