ERP For Machinery Manufacturing

Moulders Consulting: Offering A Top-Quality ERP For Machinery Manufacturing

At Moulders Consulting, we craft tailor-made MRP/ERP for machinery manufacturing.

Developed by seasoned manufacturing professionals with over 40 years of collective experience, our systems are finely tuned to meet the unique needs of the sector. Our team comprises experts from diverse backgrounds, including sales, marketing, operations, and management, ensuring a comprehensive approach to your business needs.

By leveraging the expertise of our team, we’ve successfully introduced cutting-edge MRP/ERP systems to the machinery manufacturing landscape. This has translated into streamlined processes, enhanced operational efficiency, and improved outcomes for our clients.

Material Requirements Planning (MRP) systems lie at the heart of manufacturing operations, managing material requirements throughout the production process. From developing production schedules to assessing material needs and monitoring inventory levels, our MRP solutions proceed through six essential steps:

Production Schedule Development: Tailoring production schedules to customer demand and inventory levels, setting the stage for the production plan.

Material Requirements: Calculating material needs based on product volume, type, and quantity, including allowances for waste.

Inventory Check: Ensuring inventory levels meet material demands.

Purchase Order Generation: Generating purchase orders for required materials when resources are insufficient.

Progress Tracking: Monitoring the progress of purchase orders, including delivery dates and any associated issues.

Plan Adjustment: Adapting production schedules as needed in response to changes in the plan.

With our meticulously crafted solutions, we help machinery manufacturing businesses optimise their operations and drive success in the fast-evolving industry landscape.

Mark Amphlett

Director

Need help? Contact me

01626 903 151 or mark@mouldersconsulting.co.uk

What Is An ERP For Manufacturing?

ERP systems, short for Enterprise Resource Planning, serve as essential tools for managing and organising operations within your manufacturing business. By facilitating seamless data transfer and information exchange, these systems promote efficiency and ensure smooth workflows for your staff, ultimately contributing to the overall success of your business.

About Our ERP/MRP Solutions

Our software offers a comprehensive solution for your MRP and ERP requirements. It merges the advantages of both systems, empowering manufacturers to enhance their operational management effectively.

Tailored for the machinery manufacturing industry, our fully integrated product management solutions elevate performance standards, ensuring more efficient processes.

We take pride in successfully implementing our ERP and MRP systems across companies of all sizes in the manufacturing sector. Reach out to us today to discover more about our cutting-edge software solutions!

Looking For A Top-Quality ERP For Machinery Manufacturing? Give Us A Call!

Want to know what our ERP solutions can do for you?

MCL Software - for the Injection Moulding Industry

Over 40 years experience within the Plastics Industry

2023 - The Year For Efficiency!

An all-encompassing, tried and tested ERP / MRP for the Injection Moulding Industry – the core software has been developed to cater for our complex industry, and we have the knowledge and grass routes experience having worked within Injection Moulding Factories, to fully understand the improvement in efficiencies required to make an ERP / MRP implementation really worthwhile. Communication is the key! Scroll on down to see just some of the key features of MCL Software.

MCL Software - Key Features

DASHBOARD – designed to give an overview of your facility – broken down into sections to include

Sales | Quotes | Purchasing | Production | Quality | Delivery

Navigate easily from your dashboard to access all ERP / MRP info – even through to production planning.

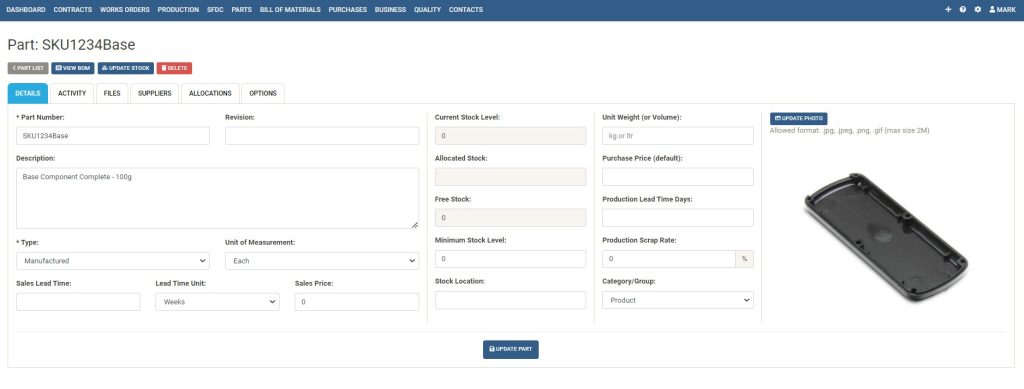

PARTS – see all of the information you need to about any manufactured or bought in part on one simple to use screen. Here you will have an overview of the following:

Part Details | Activity | Files | Suppliers | Allocations | Options

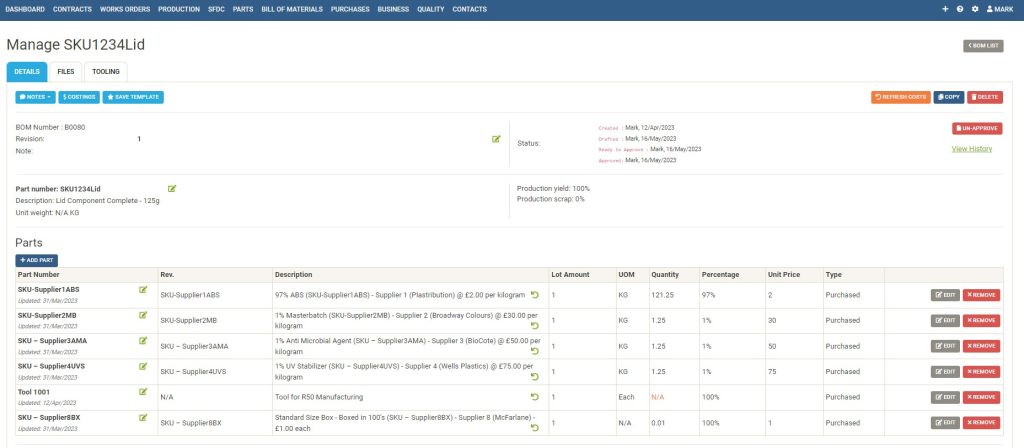

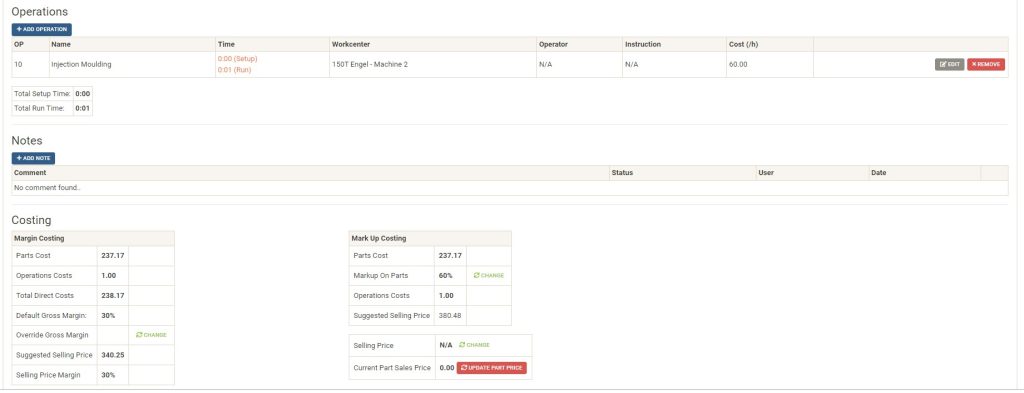

BOMS – easy to navigate and populate – able to select multiple items easily on the Bill of Material in a variety of units, including percentages to jobs which may include Masterbatch, UV Stabaliser, Powders, Anti-Microbial agents etc.

Add files, quality documents, C of C’s, and tooling data to ensure all relevant detail can be accessed in one clear and concise location.

BOMS – You then delve deeper into the detail of the specified machine best suited for the manufacture of this component and add on any ancillaries required including robots, conveyors, dryers, and even the human resources required for production.

Add notes that are relevant to the job, and the additional bonus of the costing calculator gives you the ability to track profitability, and calculate price breaks by relating the part cost, to various quantities, and your required margin.

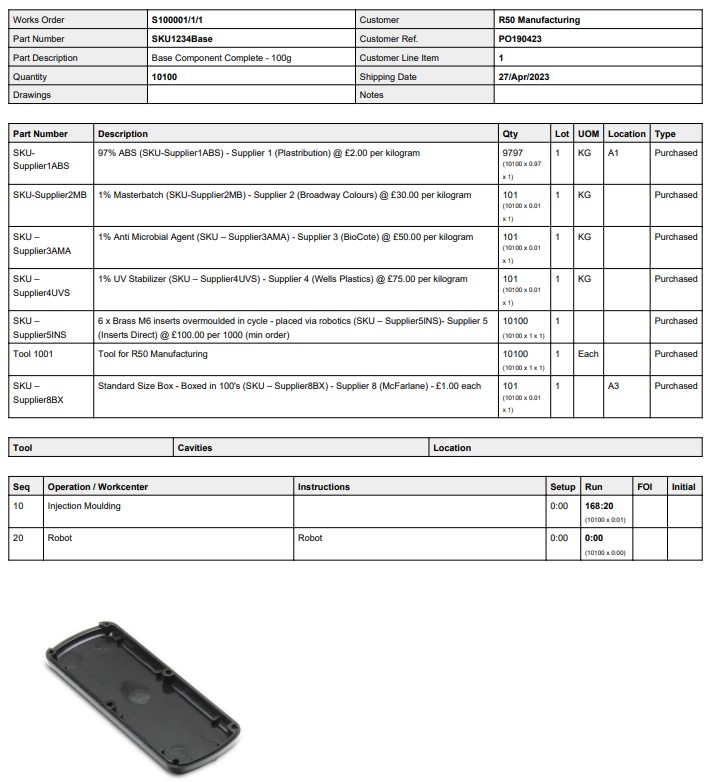

JOB CARD – All of the right information, all in the right place. The MCL Job Card clearly shows the following:

Work Order No. | Part Number | Description | Job Quantity | Drawing

Customer | P/O Ref No | Order Line | Date | Notes

BOM details, to include quantities, weights, units of measure, locations, and type of product

Tool information, including location, change inserts, and cavities are provided

Allocation of machines and any ancillaries required to complete production

And finally, the image of the part itself to help the production personnel to keep on track.

MCL Software - Key Features

Tooling Register

Incorporating a full tooling register, maintaining your clients tooling status and location

BOM's

Multi-level Bill Of Materials, to include sub-assemblies, and final assemblies

Production Planning

Visual Capacity planning and scheduling, by the Week, Day and even Hour

Job Cards / Works Orders

A clear visual document for shop floor use - including BOMs for Injection Moulding

Contacts

Full customer and Supplier data capture with CRM Traceability and email capabilities throughout

Traceability

Ability to trace material from Purchase Order through WIP to final moulded component

Second Operations

Ability to track manufacturing flow to clearly identify secondary operations and manual operations

Purchasing

Full purchase planning auto updated customer sales order demand, and stock allocations

NCR / Quality

Track all non-conformance reports and corrective actions, integrated with part record

Shop Floor Data Capture

Real time data collection from production - tracking all processes and works orders / job cards

Dashboard

Snapshot insight into daily business expectations, monitoring progress in real time

Invoicing

Raise invoices using our invoicing module, integrated directly with Sage, Xero & Quickbooks

About Us

At Moulders Consulting Ltd., we take pride in being specialist providers of ERP/MRP software tailored to the machinery manufacturing sector. Our mission is to help manufacturing companies produce top-quality products by boosting operational efficiency and reducing production costs, leading to sustainable long-term growth for our clients.

We understand the unique needs of machinery manufacturing businesses, drawing from our expertise in plastic injection moulding and Industry 4.0 advancements. Our services cover a wide range of solutions, including ERP/MRP systems advice, MES implementation, production process optimisation, e-commerce solutions, marketing strategies, troubleshooting, and more.

With our cost-effective consultancy and solutions, we enable your business to deliver premium products and services while enjoying increased profit margins. Our software caters to manufacturing companies with annual turnovers ranging from £1M to £25M.

Contact us today to discover how our software can help your business achieve higher profit margins and sustainable growth!

About Our Directors

About Mark Amphlett

With more than two decades of experience in the plastics industry, Mark Amphlett has been a key figure in the growth of Amtek Plastics in Newton Abbot, serving as General Manager.

Under his leadership, the company’s annual turnover skyrocketed from £650k to over £3M in less than six years. Mark’s effective branding strategies positioned Amtek Plastics as a leading provider of Plastic Injection Moulding services in the UK, resulting in a significant surge in inbound inquiries, from an average of 3 or 4 per month to well over 60.

These achievements underscore Mark’s exceptional marketing skills, unwavering dedication to fostering growth, and remarkable talent for strategically positioning businesses for success.

About Andy Jewell

Andy Jewell began his journey in the plastics industry in 1989, armed with an Honours Degree in Chemistry with Business Administration.

During his early career, Andy honed his skills in sales and developed his technical expertise in material handling, drying, and dosing systems, as well as real-time Manufacturing Execution Systems (MES) for the Plastics sector.

As his proficiency in the Plastic Injection Moulding sector flourished, Andy transitioned into promoting and selling real-time Manufacturing Execution Systems (MES) for the Plastics industry.

Collaborating closely with a renowned US-based supplier of MES/SFDC/i4.0 solutions, Andy played a pivotal role in establishing them as a leading provider worldwide. His dedication and contributions were instrumental in driving the company’s success and reinforcing its reputation within the industry.

Since 2017, Andy has served as an Independent Sales Consultant, leveraging his deep understanding of the plastics industry and expertise in MES solutions to become a trusted advisor and consultant.

In this role, his unwavering commitment to excellence and delivering tangible results has empowered countless clients to achieve enhanced productivity and profitability.